Surveying and Design of Niemon Canal Hydro Power Plant Construction Project

Small-to-Medium sized Hydroelectric Power Generation, Fiscal year 2008, Toyama Prefecture

In handling the construction of this power plant, we were responsible for the implementation design, surveying, and support for the preparation of various application materials.

(1) Outline of power generation plan

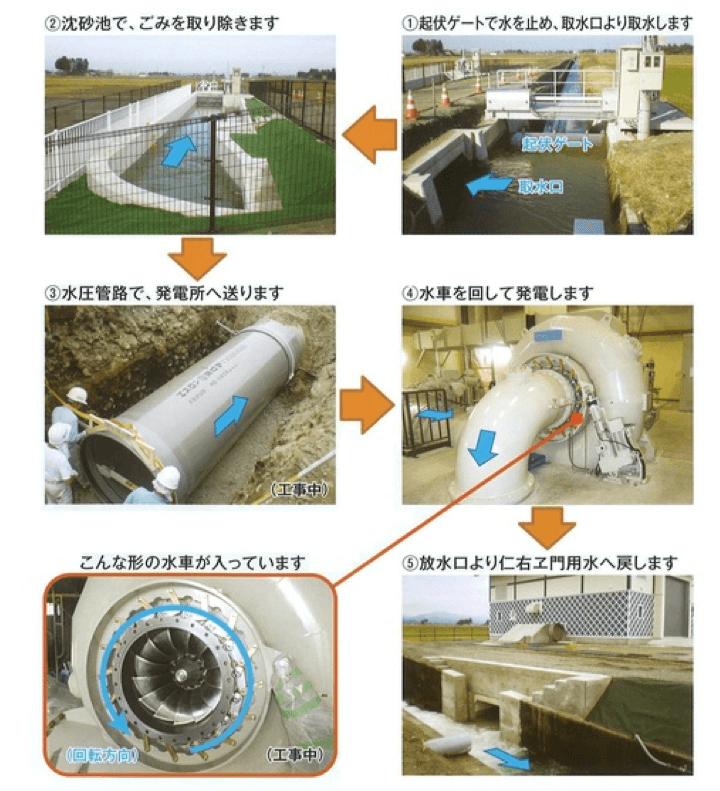

The power plant uses a maximum of 2.40 m3/s of water. Water is guided from a water tank (head tank) down along a hydraulic pipeline over a distance of approximately 1,400 m to a power generator, over an effective drop of 24.48 m, to generate a maximum of 460 kW of power. The plant is designed to supply a total of about 3.50 million kWh of electricity per year.

To carry out power generation, a water gauge is installed in the water tank (head tank) at the starting point of the hydraulic pipeline and then the water turbine guide vanes are automatically adjusted based on the measured water level, so that the water tank level remains constant. (Water level adjustment operation)

The turbine is a horizontal Francis turbine, and the generator is a horizontal 3-phase induction generator.

In the planning and implementation of the power plant, we handled the basic design, implementation design, construction design, support for the preparation of various application materials, and supervision of construction work.

(2) Outline of generating electricity plan

The power plant uses a maximum of 2.40 m3/s of water. Water is guided from a water tank (head tank) down along a hydraulic pipeline over a distance of approximately 1,400 m to a power generator, over an effective drop of 24.48 m, to generate a maximum of 460 kW of power. The plant is designed to supply a total of about 3.50 million kWh of electricity per year.

To carry out power generation, a water gauge is installed in the water tank (head tank) at the starting point of the hydraulic pipeline and then the water turbine guide vanes are automatically adjusted based on the measured water level, so that the water tank level remains constant. (Water level adjustment operation)

The turbine is a horizontal Francis turbine, and the generator is a horizontal 3-phase induction generator.

Outline of power generation

(2) Features of the design project

1. The irrigation water head is integrated for the purpose of power generation

Multiple hydraulic drops are installed along the Niemon Canal. The head between each hydraulic drop is small, but by combining them (guiding water along the canal from the most upstream to the most downstream point) it was possible to achieve a drop of more than 20 meters.

This power station was probably the harbinger in “integrated head” style generation plants, which have become mainstream in recent years.

2. Hydraulic pipeline cost is reduced

Since the hydraulic pipeline (buried in the soil) extends for a length of 1,400 m, it was an important challenge to minimize costs for this part of the work. By employing FRPM (Fiberglass Reinforced Plastic Mortar) pipes for the hydraulic pipeline, we managed to limit construction costs considerably.

For refill materials, we tried to make effective use of natural resources and reduce costs, so in the end we opted for environment-friendly and creative solutions, using recycled aggregate, for example.

From the project head

This power plant pioneered the technique of combining multiple hydraulic drops along irrigation canals for the purpose of power generation. In fact, this was Japan’s first prefecture-managed hydro power plant utilizing irrigation water.

Civil engineering is often said to be “experience engineering” (experience is fundamentals for civil engineering), Especially in hydroelectric power generation, it is necessary to pay close attention to maintainability after commencing operation too. I think the experiential engineering aspect of this project was strong.

The design of a hydro power plant requires knowledge of a wide variety of fields, including civil engineering, machinery, and electricity, as well as the ability to cooperate with assorted manufacturers. On top of this, it is necessary to consult and coordinate with a variety of application agencies.

For these reasons, I believe that the most essential quality of engineers involved in hydroelectric power generation is an ability for comprehensive coordination. At the time of this project, I was not yet fully developed in this area, so I had a hard time.

I realized very clearly through this project that in addition to individual capabilities, it is also vital to establish a team that can cooperate successfully.

Masayuki Shimazu, Department of Second Civil Engineering Works